Product Overview

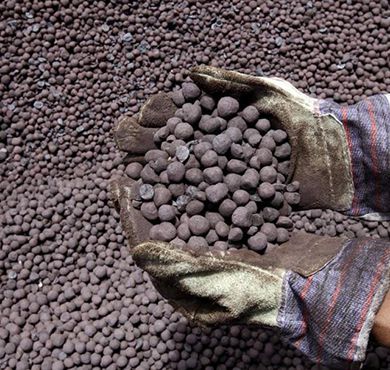

IOP Grade Bentonite stands for Iron Ore Pelletization grade. It is a highly specialized sodium bentonite designed specifically for the steel industry. Its primary job is to turn powdery iron ore "fines" into hard, spherical pellets that can be fed into a blast furnace or Direct Reduced Iron (DRI) plant.

Key applications in steel production:

- Iron ore pellet binding

- Blast furnace feed preparation

- Direct Reduced Iron (DRI) plants

- Steel industry pelletization

Our IOP Grade Bentonite is specially processed to provide exceptional binding strength, low silica content, and high thermal stability, making it ideal for producing high-quality iron ore pellets.

Superior Binding

Green & dry strength

Low Silica

Optimized SiO₂ content

Thermal Stability

1200-1300°C resistant

High Iron Recovery

0.5-1.0% dosage only

Benefits of IOP Grade Bentonite

Our IOP Grade Bentonite is engineered specifically for iron ore pelletization in the steel industry. Its unique properties ensure maximum production efficiency and pellet quality.

Here are the primary benefits of using IOP grade bentonite:

1. Exceptional Binding Strength (Green & Dry)

In the pelletizing process, iron ore powder is rolled into "green" (wet) balls.

Green Strength: IOP bentonite provides the immediate "tackiness" needed to hold the wet ore together so the balls don't crumble while being transported to the kiln.

Dry Strength: As the pellets dry, the bentonite creates a strong mineral bridge that prevents them from cracking or turning back into dust before they are fired.

2. Low Silica Content (SiO₂)

One of the unique requirements of IOP grade is a controlled chemical profile.

The Benefit: High-quality IOP bentonite is processed to have lower silica than standard industrial clay. Excess silica in the pellet creates unwanted "slag" in the blast furnace, which wastes energy and reduces the efficiency of steel production. Using IOP grade keeps the iron-to-silica ratio optimal.

3. Thermal Stability & Shock Resistance

Pellets are subjected to extreme heat (up to 1,200°C to 1,300°C) very quickly.

The Benefit: IOP grade bentonite has high thermal durability. It prevents the pellets from exploding or "spalling" when they hit the high temperatures of the indurating machine (kiln). This ensures a high "yield" of usable pellets with minimal waste.

4. High Iron Recovery

Unlike some binders that "dilute" the iron content of the pellet, IOP grade is often selected for its compatibility with the ore.

The Benefit: Because it is so effective, you only need a very small amount (typically 0.5% to 1.0% by weight). This allows the final pellet to maintain a very high iron (Fe) percentage, which is the most valuable part of the product.

5. Faster Pellet Growth Rate

The "swelling" and "water absorption" properties are finely tuned for the speed of the pelletizing disc.

The Benefit: It absorbs excess moisture from the ore concentrate rapidly, allowing the pellets to form and grow to the desired size (9mm to 16mm) much faster. This increases the overall production capacity of the plant.

Technical Specifications

For detailed specifications and technical data sheets:

Request Specifications