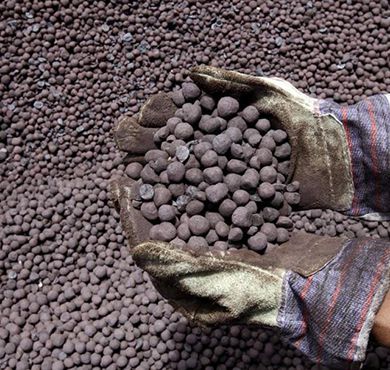

Product Overview

Earthing Grade Bentonite (also known as Ground Enhancement Material) is a specialized sodium-based clay used to improve the performance of electrical grounding systems. It is installed around earth electrodes (rods, plates, or mats) to ensure that fault currents and lightning strikes can safely dissipate into the ground.

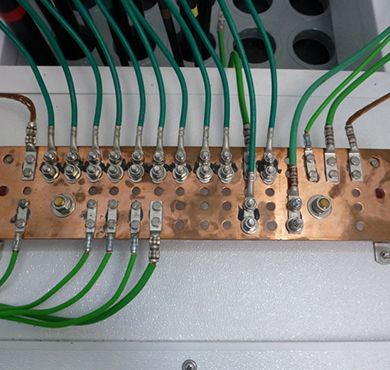

Key applications in electrical safety:

- Electrical grounding systems

- Lightning protection installations

- Substation and power plant earthing

- Tower and telecom grounding

Our Earthing Grade Bentonite is specifically formulated to provide exceptional conductivity, moisture retention, and long-term stability in all soil conditions and climates.

Low Resistivity

Reduces resistance by 80%

Moisture Retention

Absorbs 5x its weight

Corrosion Protection

Non-corrosive to metals

Maintenance-Free

15+ year lifespan

Benefits of Earthing Grade Bentonite

Our Earthing Grade Bentonite is engineered to provide superior electrical grounding performance. Its unique properties make it essential for safe and effective electrical installations.

Here are the primary benefits of using earthing grade bentonite:

1. Significant Reduction in Soil Resistivity

The most critical function of earthing bentonite is its ability to lower the electrical resistance of the soil.

The Benefit: It can reduce soil resistivity by up to 80%. By creating a highly conductive environment around the electrode, it ensures that electricity follows the path of least resistance into the earth, protecting people and sensitive equipment from surges.

2. Exceptional Moisture Retention

Bentonite is hygroscopic, meaning it actively absorbs and holds onto water.

The Benefit: It can absorb up to 5 times its weight in water. Unlike standard soil, which dries out in summer, bentonite retains a "gel-like" state for long periods. This keeps the grounding system active and efficient even during dry seasons or in arid climates.

3. Increased Contact Surface Area

When mixed with water, sodium bentonite swells to 15–20 times its dry volume.

The Benefit: As it expands, the clay forcedly fills every crack, void, and air pocket in the surrounding soil. This creates a massive, seamless "interface" between the copper or GI (Galvanized Iron) rod and the earth, effectively making the electrode "larger" in terms of electrical contact.

4. Corrosion Protection

Traditional grounding methods often used salt and charcoal, which are highly corrosive and eat away at metal electrodes over time.

The Benefit: Earthing grade bentonite is non-corrosive and chemically neutral. It acts as a protective "envelope" around the metal rod, shielding it from direct contact with corrosive soil chemicals and moisture, which can extend the lifespan of the grounding system to 15+ years.

5. Maintenance-Free Performance

Once installed as a slurry or backfill, bentonite does not leach away like chemical salts.

The Benefit: Because it is a natural mineral, it is stable and doesn't "expire." While traditional salt/charcoal pits require periodic "recharging" (adding more salt and water), a properly installed bentonite pit is largely maintenance-free.

Technical Specifications

For detailed specifications and technical data sheets:

Request Specifications